The Challenges of Outsourcing Teamwear Production

Why Admiral’s Local Manufacturing is the Future

The global teamwear industry has long relied on overseas manufacturing, particularly in Asia, to keep costs low and production scalable. But as delays, quality issues, and concerns over labor practices continue to plague many big-name brands, it’s becoming clear that offshore production is no longer the reliable solution it once seemed to be. In fact, many brands have found themselves at the center of a storm, with frustrated customers facing delivery delays and poor-quality gear. So, is it time for the teamwear industry to rethink its approach?

The Struggles of Offshore Production

Price hikes on apparel made in Asia

Most brands (not Admiral) make their team apparel in Asia (China, India, Thailand, Vietnam, Pakistan and Bangladesh). It is believed Donald Trump’s universal tariff proposals could cause prices to skyrocket on teamwear made in Asia. Trump has said he would impose a 10% or 20% tariff on all imports across the board and a specifically high China rate between 60% and 100%.

Quality Control Nightmares

Some brands, heavily rely on manufacturing in Bangladesh. One of the biggest issues with offshore manufacturing, there, is maintaining consistent product quality.

Their customers have reported that their teamwear, when it finally arrives, doesn’t hold up. From peeling numbers to falling patches, the quality problems are only exacerbated by long wait times. For parents and coaches relying on uniforms for an important match or tournament, this inconsistency can be devastating.

Even industry giants like Nike and Adidas have faced disruptions in their Asian factories due to labor strikes, natural disasters, and pandemics—leading to significant delays and subpar products. In 2021, Nike had to suspend operations at several factories in Bangladesh due to civil unrest, causing production delays that hurt their bottom line and reputation.

Shipping Delays

Shipping delays are another major headache. The global supply chain crisis, which was amplified by COVID-19 and now by wars in Europe & the Mid East, has wreaked havoc on overseas shipping schedules. Brands like Nike, Adidas & Cappelli have struggled with missed deadlines, inventory shortages, and even stockouts. The delays are often unpredictable—leaving customers scrambling to find alternative solutions.

For some, these delays have been a nationwide issue. Parents across the country have expressed frustration at receiving their team's gear well after the season has already started. In fact, many have found themselves waiting weeks, even months, for uniforms that were ordered well in advance.

Customer Frustration

One Beat Soccer recently published an article which highlights shared stories of waiting for uniforms long after the season began, with some players receiving their gear while others were left waiting or given partial kits. The delays have been so severe that some teams had to improvise, with players turning up to games in mismatched or makeshift gear—an issue that undermines both team morale and professionalism.

The reasons behind the delays are often linked to the same challenges faced by other offshore manufacturers—labor unrest, factory closures, shipping issues and a lack of communication

A Local Solution: Admiral’s In-House Production

So, what’s the alternative? Enter Admiral, who fifteen years ago took a bold step away from the pitfalls of Asia manufacturing. Instead of relying on far-flung factories, Admiral has invested in local production, operating its own state-of-the-art facility just a 90 minute fight from Miami. This shift has allowed Admiral to offer several key advantages that other brands simply can’t match.

Total Control Over Quality

By producing locally, Admiral has complete oversight over the entire manufacturing process. This ensures high-quality, durable products—something that’s difficult to guarantee when you're outsourcing production to distant factories. One Beat Soccer article reports customers have experienced peeling numbers and falling patches. In total contrast, Admiral’s local production ensures that every item meets strict quality standards. Sublimated logos and numbers never fade, peel or crack.

Ethical Practices and Transparency

When you manufacture near shore, you can ensure that workers are treated fairly and that labor practices are transparent. Admiral’s commitment to ethical manufacturing means safe working conditions, fair wages, healthcare provision and no sweatshops—something that’s harder to guarantee when production is outsourced to far eastern factories. This transparency resonates with customers increasingly concerned about the ethical implications of their purchases.’’

Sustainability and Reduced Carbon Footprint

With growing consumer demand for sustainable practices, Admiral’s local production model ticks the box for eco-conscious buyers who want to minimize their carbon footprint while supporting local jobs.

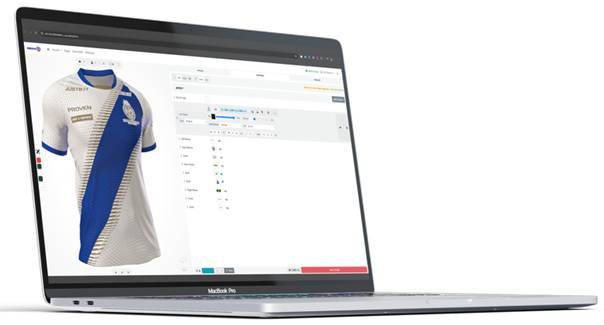

The companies Admiral ID software minimizes waste, optimizing the layout of club designs when printing, wasting less, paper, ink, fabric & energy.

Admiral ID uses sustainable recycled polyester Dry Skin fabric, sublimation paper that’s approved by the Forest Stewardship Council, water-based inks that have a lower the impact on the environment and high-speed printers require reduced drying time using less energy.

By manufacturing “on demand” closer to home, Admiral also reduces the environmental impact associated with long-distance shipping.

Faster Delivery and Shorter Lead Times

The proximity of Admiral’s factory to the U.S. means significantly shorter shipping times. Admiral also produces single units rather than waiting for all orders to be received prior to “batching production”. This translates to faster order fulfillment and more reliable delivery schedules, ensuring that teams receive their gear on time—whether for the first game of the season or for last-minute tournaments. Admiral’s production model offers certainty and consistency.

Why Local Manufacturing is the Future

The issues facing offshore teamwear production—shipping delays, inconsistent quality, and labor concerns—are prompting more and more brands to reconsider their strategies. By bringing manufacturing back home, brands like Admiral set a new standard for the industry many years ago. With superior quality control, faster lead times, and ethical practices, local production isn’t just a solution to current challenges—it’s the future of teamwear.

If you're tired of the delays, the quality problems, and the frustration of working with overseas suppliers, it may be time to consider a more local solution. Admiral Customer Reviews

Admiral’s in-house production model offers a level of reliability, speed, and sustainability that offshore manufacturing just can’t match.